In automated screw assembly lines, the single-cycle time from screw feeding to driving directly determines the overall production takt. Especially in high-capacity scenarios, even millisecond-level time savings can bring significant efficiency gains. This article proposes optimization solutions based on nail storage and coordinated operation between mechanisms for different working conditions (long-distance feeding, small length-to-diameter ratio screw feeding), achieving effective reduction of cycle time and thereby improving automated assembly line efficiency.

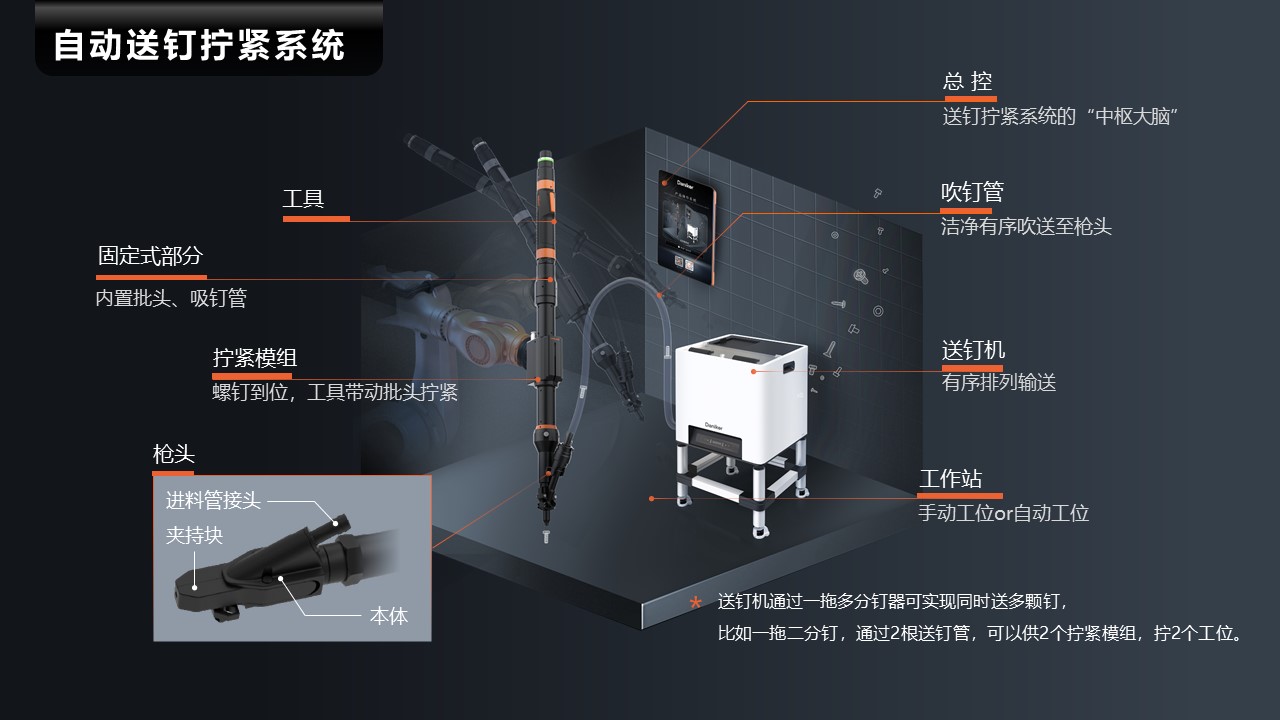

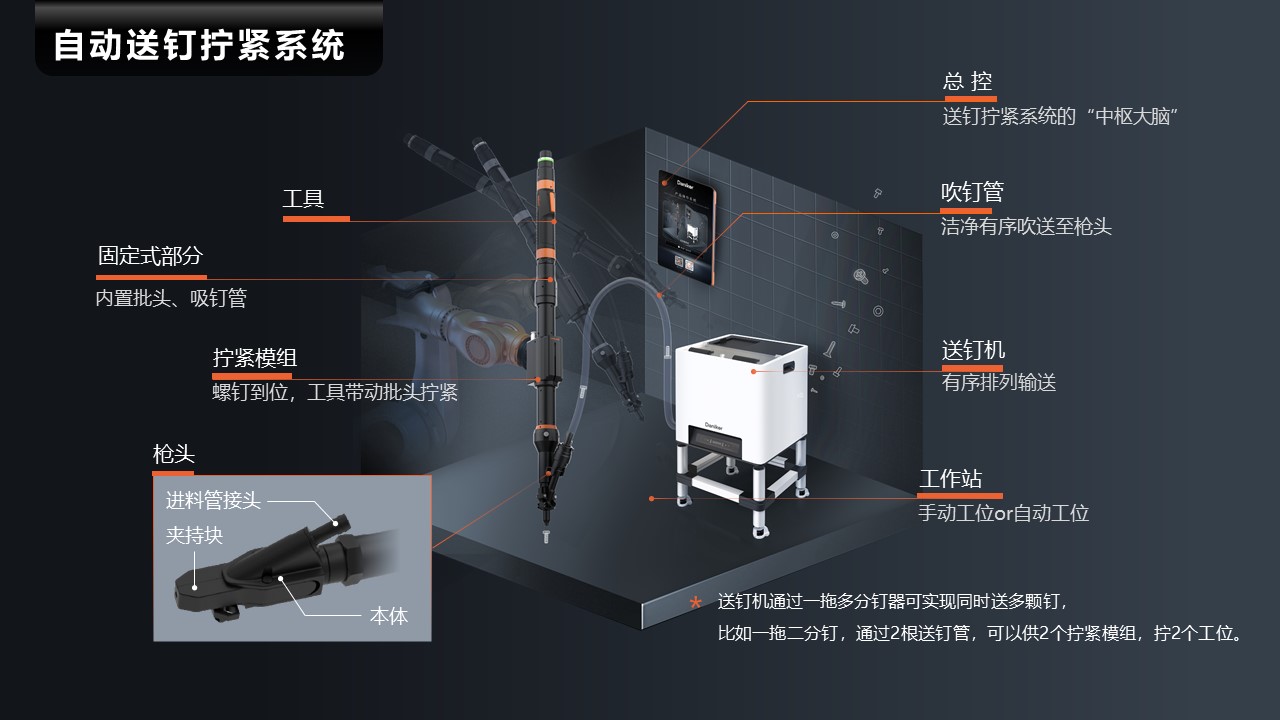

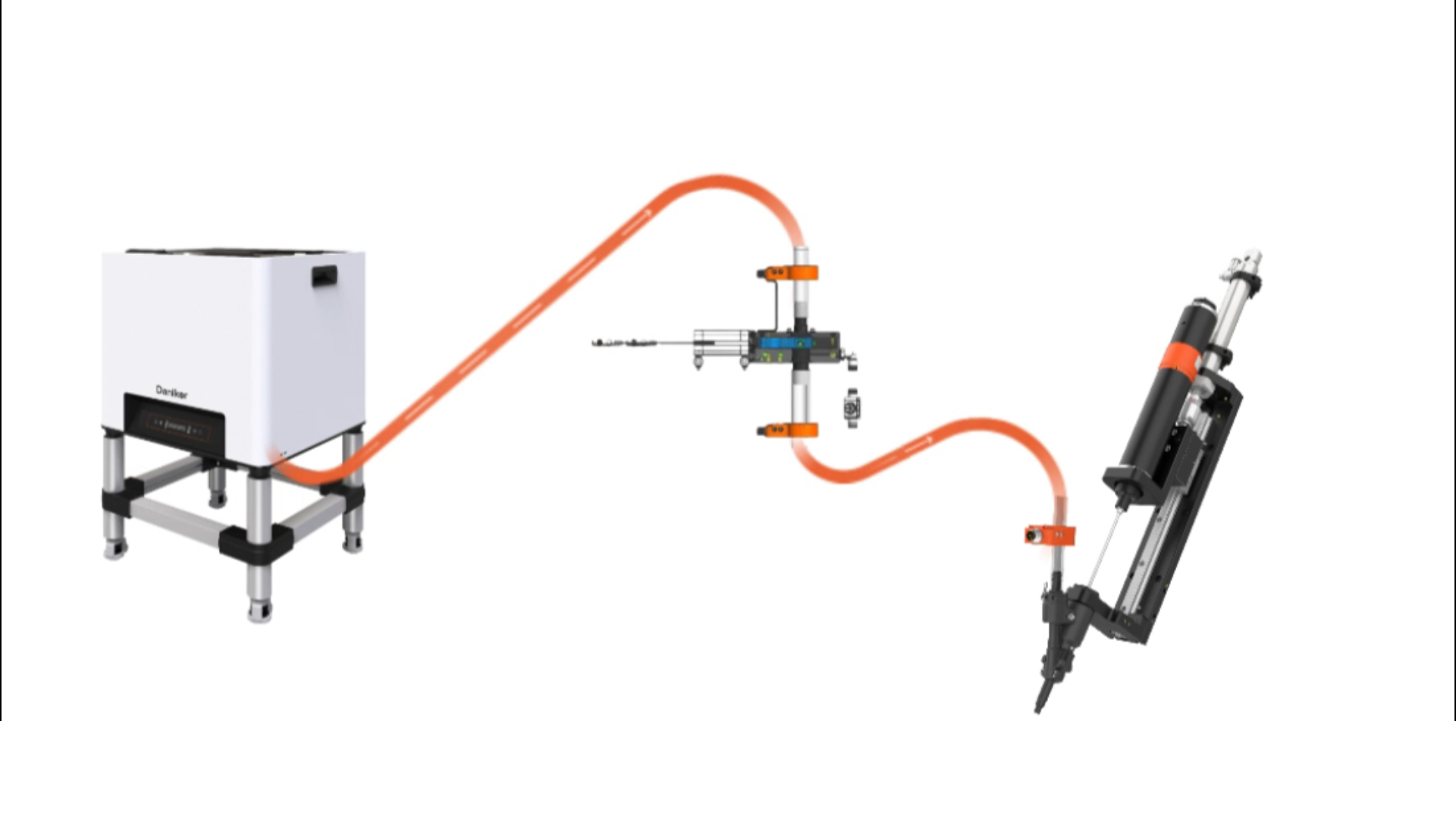

First, we need to understand the entire screw feeding process of the screw feeding system. Conventional screw feeding systems adopt a linear feeding mode of "screw feeder - conveying tube - tightening module". A single cycle needs to go through five stages: "screw feeder supplies screw → conveying tube transports → tightening execution → module reset → moves to next hole position". If the next screw only starts to be conveyed from the screw feeder to the gun head after the module completes tightening, resets and moves to the next hole position, there will be obvious waiting time, especially in long-distance conveying scenarios where time waste is more prominent. Therefore, breaking the time limitation of linear feeding is the key path to shortening single cycle time.

1. Long-distance Feeding Scenario: Addition and Timing of Nail Storage Module

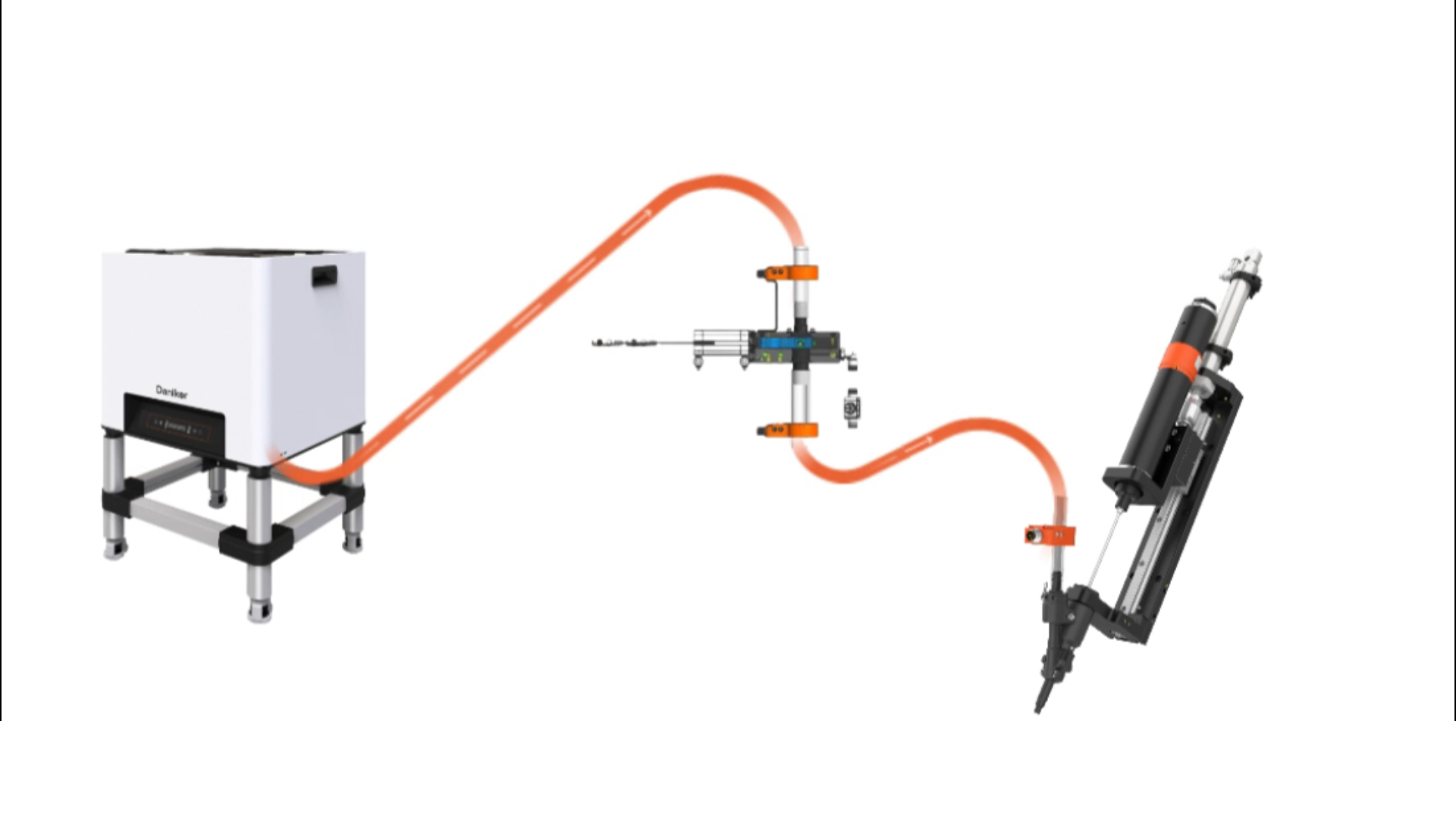

For the pain point of long-distance coordination, by adding a nail storage module near the tightening module, a two-stage feeding architecture of "screw feeder - storage module - tightening module" is constructed to shorten the screw feeding stroke, and during the process of module reset and movement, the next screw is blown to the gun head in advance to save time. The specific operation logic is as follows:

The module drives the tool to complete the current screw tightening

While tightening, the screw feeder blows the next screw to the storage module

The module resets and moves to the next hole position

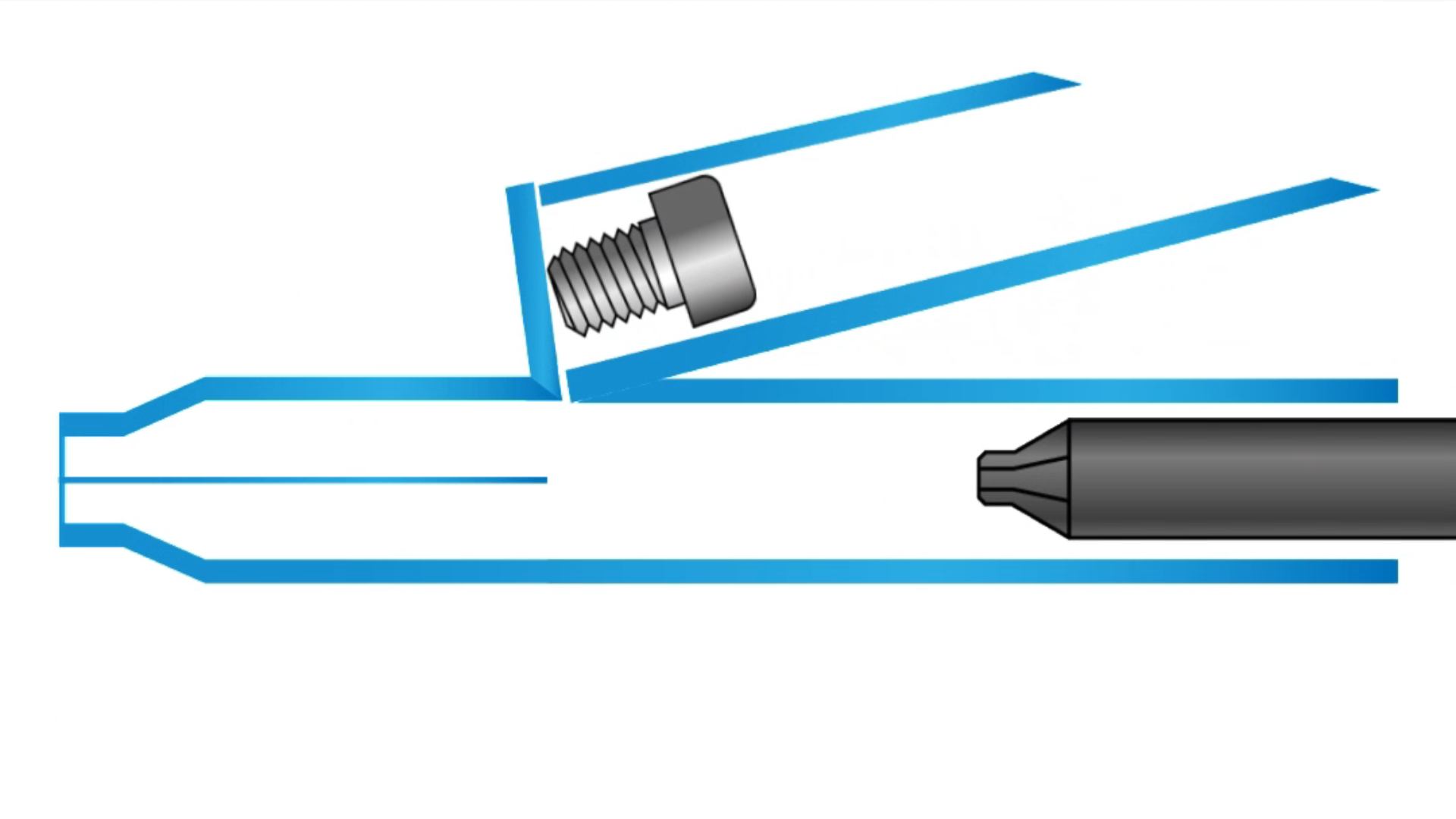

During reset and movement, the storage module blows the next screw to the gun head through the blow tube (for blow-suction types, the suction tube can also descend in advance to suck the screw)

When the module reaches the target position, the gun head already holds the pre-fed screw and directly starts the tightening action

Through the dual strategies of the storage module "shortening the screw feeding stroke" and "timing parallel optimization", the efficiency bottleneck of long-distance coordination between the screw feeder and tightening module can be effectively solved, providing a low-cost, high-compatibility optimization solution for automated assembly lines.

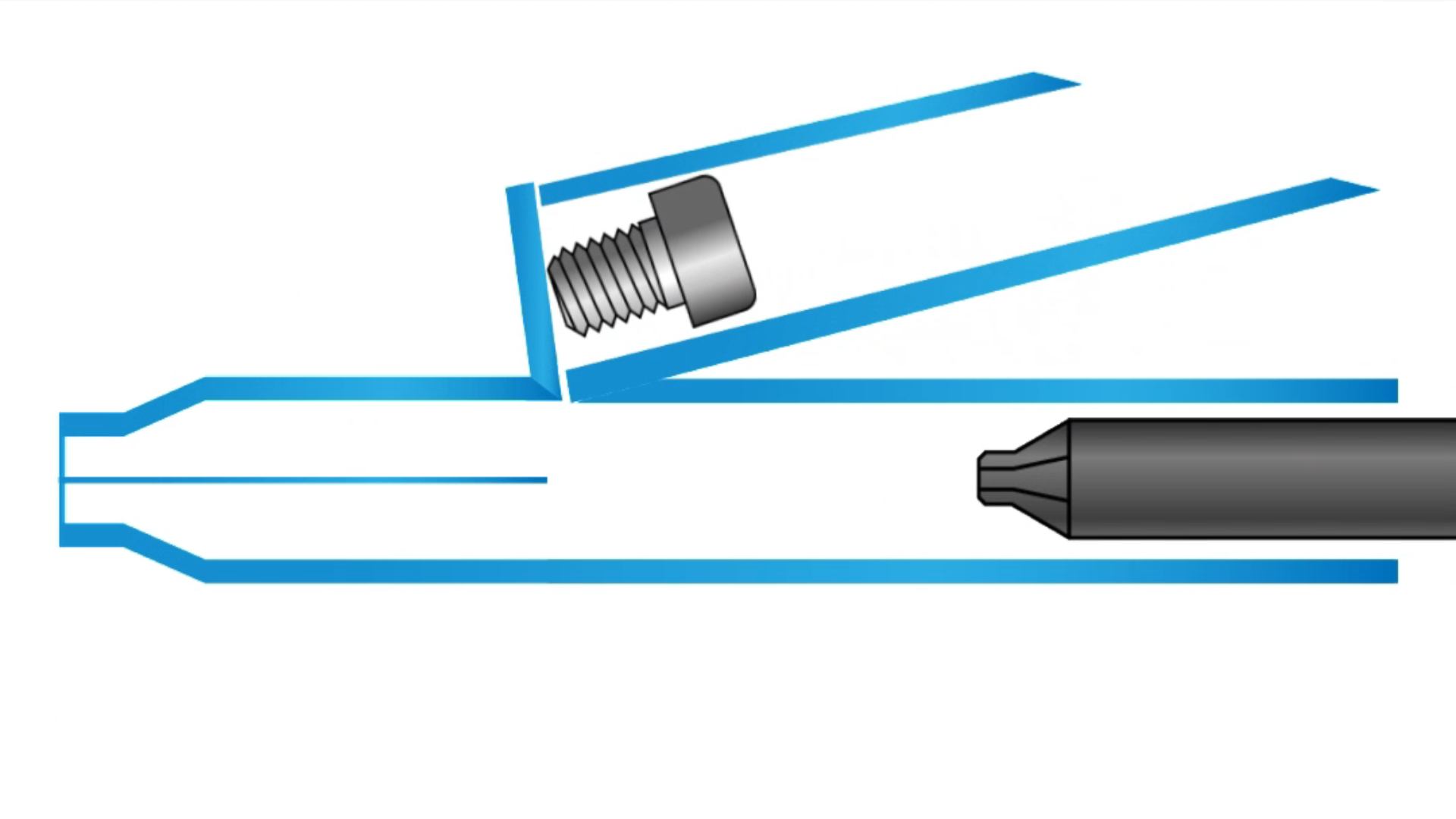

2. Small Length-to-Diameter Ratio Screw Scenario: Application of Swing Arm Tightening Module with Nail Storage

For screws with a length-to-diameter ratio <1.6, conventional gun heads are prone to nail flipping at the three-way junction, causing feeding failure. The swing arm tightening module solves both stability and efficiency problems through the special structural design of a swingable feeding channel, achieving "parallel tightening and pre-storage". The specific operation logic is as follows:

The module drives the tool to complete the current screw tightening

While tightening, the screw feeder blows the next screw to the swing arm, completing pre-storage of the next screw

The module resets, and the screw directly falls into the gun head, achieving seamless connection between "tightening - nail storage"

The module moves to the next hole position and directly performs tightening

The swing arm design integrates the nail storage function inside the gun head, eliminating the need for an external storage module, making the overall structure more compact and the cost lower. Therefore, many production lines also apply this structure to conventional screw locking to achieve high takt requirements at low cost.

For the efficiency bottleneck of screw feeding systems, the two optimization solutions proposed in this article both take "breaking the timing limitation of linear feeding" as the core logic, achieving dual improvements in cycle time compression and assembly stability, without requiring large-scale reconstruction of existing production lines. Only PLC timing optimization and modular component installation are needed to achieve upgrades, providing manufacturing enterprises with a "low cost, high efficiency" transformation path.