In industrial manufacturing, the tightening quality of bolts/screws directly determines product reliability. Since tightening processes vary significantly across different products, servo screwdrivers must support multiple tightening strategies to meet diverse fastening requirements. Even with just torque and angle as parameters, three strategies can be formed: “Torque plus Angle,” “Torque or Angle,” and “Torque and Angle.” Their control logic and applicable scenarios differ markedly. This article provides an in-depth analysis of these three strategies.

Before detailing the strategies, it’s essential to clarify the relationship between torque/angle and clamping force. Clamping force is the ultimate goal of bolt fastening, but it cannot be measured directly—only inferred indirectly through torque and angle.

Torque: The rotational force applied to the bolt. Higher torque generally increases clamping force but is heavily influenced by friction (e.g., oil on screw surfaces, debris in threaded holes).

Angle: The rotation during tightening. With fixed thread specifications, angle directly correlates with bolt “insertion depth,” offering a more accurate reflection of clamping force changes.

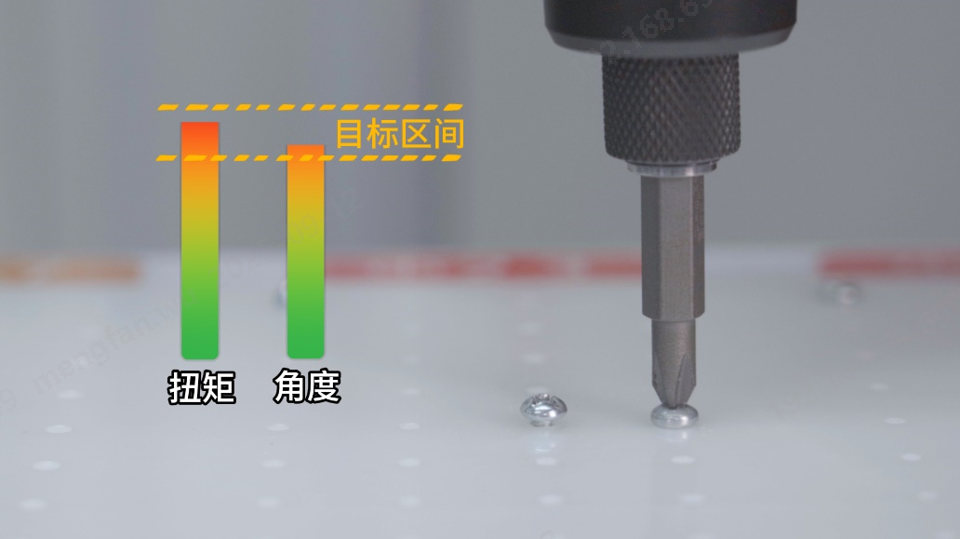

The essence of a servo screwdriver is to indirectly control clamping force by presetting “torque-angle” rules, comparing real-time sensor data against thresholds, and triggering a stop command. The core difference among the three strategies lies in how they logically evaluate “torque threshold” and “angle threshold.”

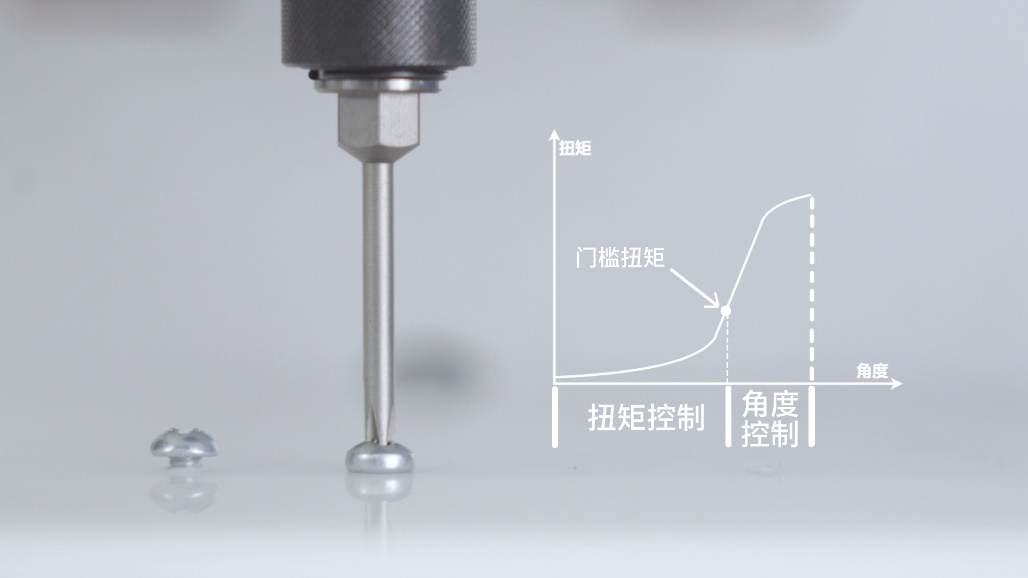

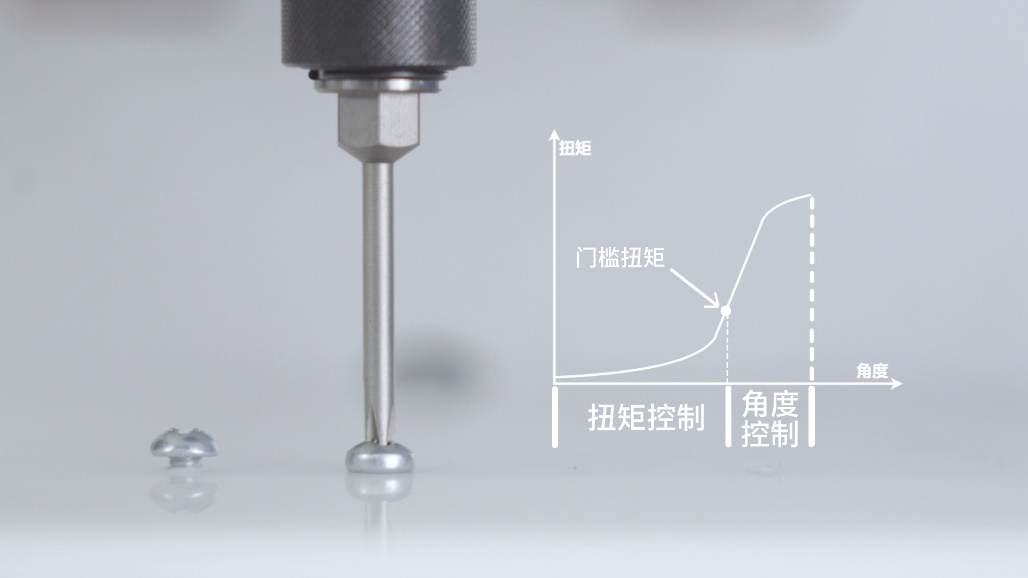

(1) Torque plus Angle: Eliminate Friction Interference via Two-Stage Control

“Torque plus Angle” is a two-stage strategy with the logic: “First ensure contact, then precisely control clamping force.”

Stage 1 (Pre-tightening): The servo screwdriver operates in torque-control mode until the preset torque is reached, then switches to angle-control. This eliminates gaps in contact surfaces (e.g., gasket rebound, assembly tolerances) to ensure full workpiece contact.

Stage 2 (Final tightening): The screwdriver switches to angle-control, rotating by a preset angle regardless of torque changes, stopping once the angle is achieved.

Since the final angle directly corresponds to bolt elongation, this strategy avoids friction-induced errors and delivers high-precision clamping force. It suits applications demanding uniform clamping force, such as automotive chassis bolts or engine critical joints, where friction variability is the main quality risk.

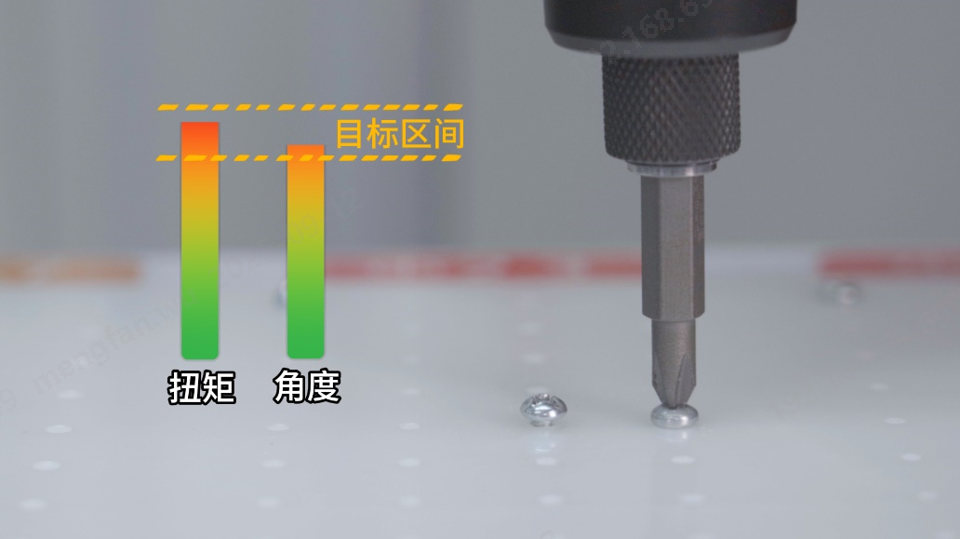

(2) Torque or Angle: Either Parameter Triggers Stop—Ideal for Low-Consistency Parts

“Torque or Angle” is a fault-tolerant strategy: “Stop immediately when either torque or angle reaches its threshold.”

Operators preset target torque and angle. If assembly resistance is low (e.g., oversized hole), angle may be reached first; if resistance is high (e.g., undersized hole), torque may be reached first. Either event stops the process, preventing over-tightening and workpiece cracking.

This dual-threshold, either-trigger logic mitigates risks of single-parameter control, making it suitable for parts with high variability, such as home-appliance assembly where plastic hole positions differ across batches.

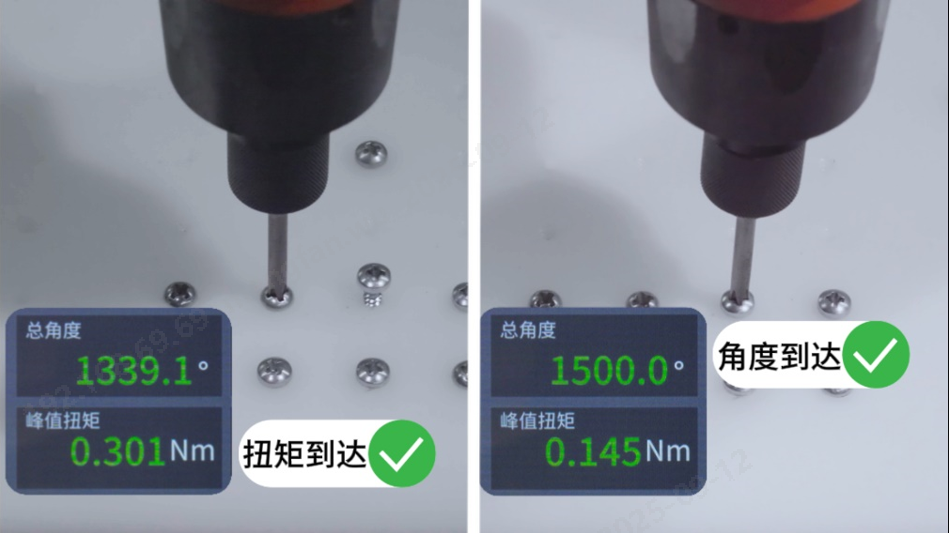

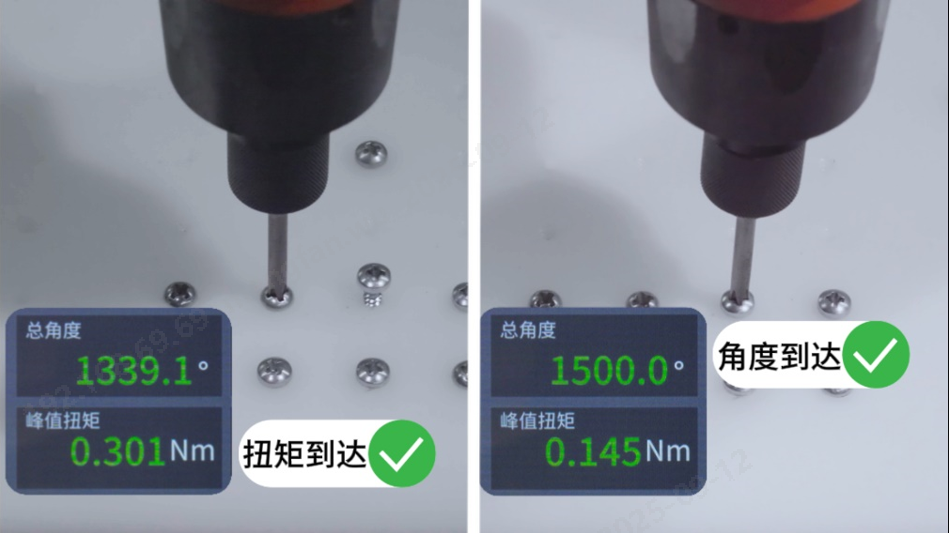

(3) Torque and Angle: Both Must Hit Thresholds—Eliminates False Tightening

“Torque and Angle” requires “both parameters to reach their thresholds before stopping—neither can be missing.”

If torque is achieved but angle is insufficient, the screwdriver continues until angle is met; vice-versa. The final pass still demands both values within spec. This dual validation effectively eradicates false tightening, critical for high-safety or aerospace/medical components where a single loose joint could cause catastrophic failure.

For manufacturers, selecting the correct strategy not only boosts product quality but also cuts after-sales costs. As new-energy, aerospace, and other sectors demand ever-higher fastening quality, refined application of advanced strategies will become an industry trend.