Flexible Feeding Systems: The Optimal Solution for Solving Multi-Variety, Small-Batch Automated Feeding Challenges

In the field of industrial automated assembly, the feeding method directly determines the flexibility, efficiency, and future expansion capability of the entire production line.

As product speeds accelerate and SKU numbers increase, traditional vibration bowl feeders and fixed feeding methods are gradually exposing their limitations, making flexible feeding systems the preferred choice for an increasing number of manufacturing enterprises.

I. What is a Flexible Feeding System?

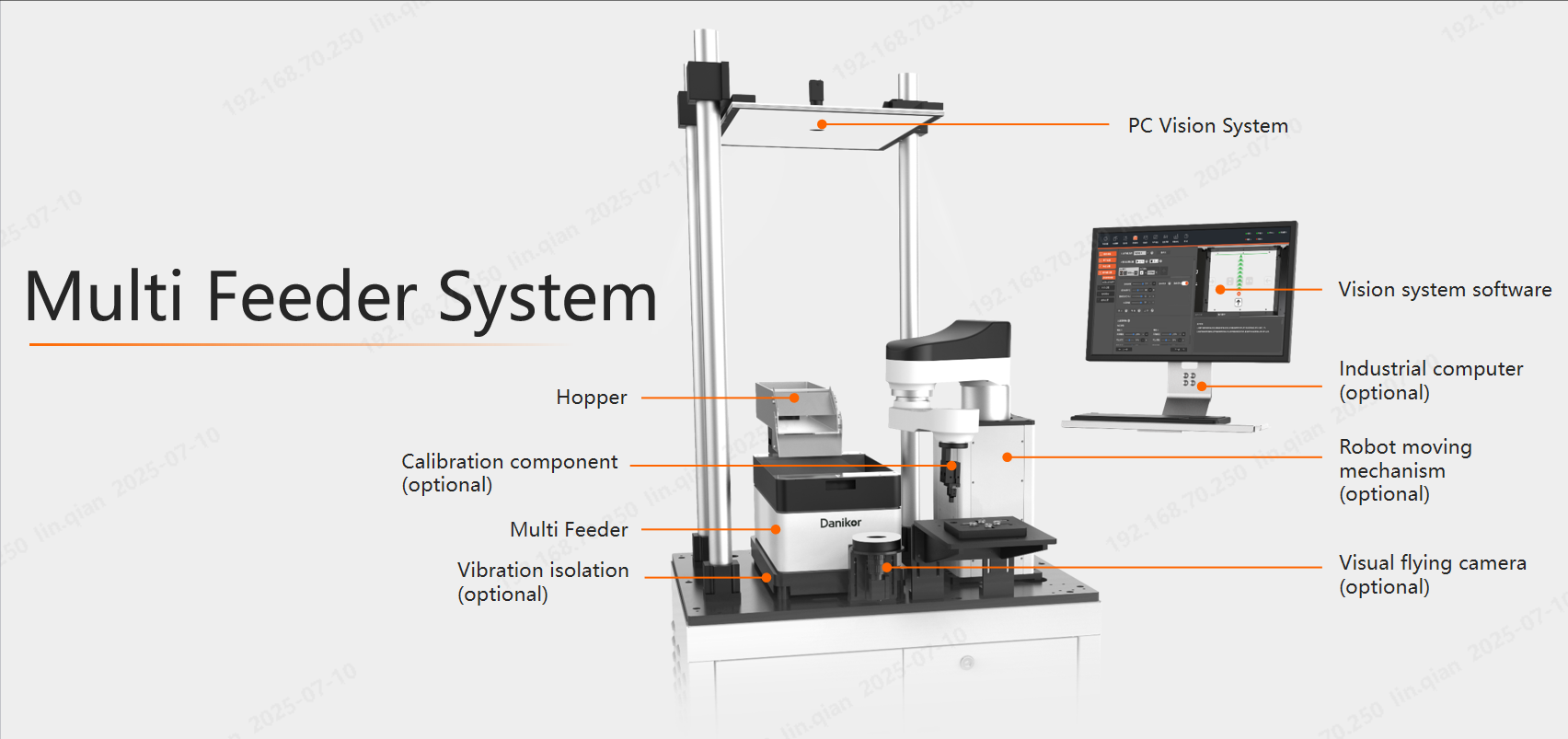

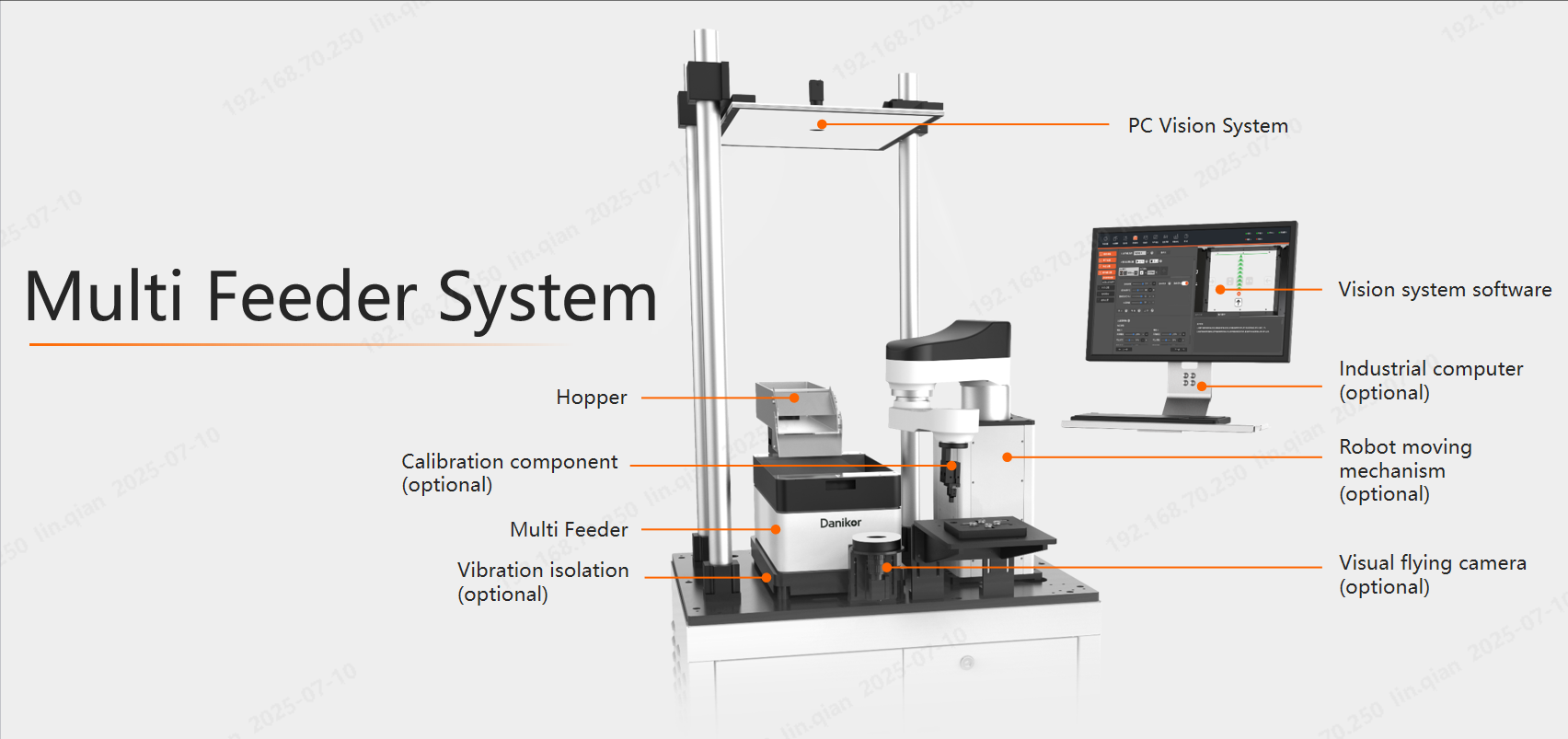

A flexible feeding system is an intelligent feeding solution that combines flexible feeding devices, vision recognition systems, and industrial robots to achieve automatic identification, positioning, and grasping of multi-variety components.

Unlike traditional feeding equipment, flexible feeding systems do not rely on fixed tracks or fixtures but instead complete component adaptation and switching through software and vision algorithms, truly achieving one system adaptable to multiple products.

Common flexible feeding systems typically consist of the following components:

Flexible Vibration Bowl Feeder

Industrial Camera / Vision Recognition System

Robot (SCARA / Six-Axis / Collaborative Robot)

II. Why Are More and More Enterprises Choosing Flexible Feeding?

In industries such as automotive components, 3C electronics, and new energy, multi-specification, multi-model products coexist. Traditional feeding methods have high changeover costs and long cycles, seriously affecting production line efficiency.

Flexible feeding systems can quickly adapt to different components through parameter switching and vision recognition, achieving true flexible production.

Although vibration bowl feeders remain effective for high-volume production of single components, they are clearly limited in the following scenarios:

Frequent product changeovers

Complex or irregular component shapes

Short new product development cycles

In comparison, flexible feeding systems can replace multiple vibration bowl feeders, significantly reducing long-term equipment investment and maintenance costs.

III. Core Advantages of Flexible Feeding Systems

Whether regular or irregular-shaped components, flexible feeding systems can complete automatic positioning through vision recognition, suitable for: hardware components, fasteners, precision electronic parts, irregular-shaped workpieces, etc.

Only program and parameter adjustments are needed without mechanical structure replacement, significantly shortening changeover time, making it very suitable for multi-variety, small-batch production modes.

Flexible feeding systems can be seamlessly integrated with: automatic tightening systems, assembly workstations, and robotic assembly lines to build highly automated flexible assembly lines.

In the process of manufacturing upgrading toward intelligence and flexibility, flexible feeding systems have become an important component of automated production lines. They not only solve the challenges of multi-variety feeding but also provide greater space for future production line expansion and product upgrades.

If your production line is facing frequent changeovers, high manual dependency, or feeding efficiency bottlenecks, a flexible feeding system will be a solution worth serious consideration.