How to Achieve Stable Pneumatic Conveying of Small Aspect Ratio Screws in Automatic Screw Feeding Processes

In automated manufacturing and assembly scenarios, automatic screw feeding technology serves as a critical support for improving assembly efficiency and ensuring operational consistency. Through automatic screw feeding equipment, automatic conveying, positioning, and supply of screws can be achieved, reducing errors and inefficiencies caused by manual intervention. However, in practical applications, the adaptability of different screw specifications to automatic screw feeding systems varies significantly. Especially for small aspect ratio screws with a length-to-diameter ratio ≤1.3, problems such as screw flipping and jamming easily occur during automated conveying, directly impacting production schedules. How to achieve stable pneumatic conveying of small aspect ratio screws has become a core requirement for many manufacturing enterprises to optimize their automatic screw feeding processes.

The core value of automatic screw feeding technology lies in achieving standardized conveying and supply of screws through a combination of mechanical and pneumatic methods, matching the operational rhythm of automated tightening equipment. For screws with reasonable length-to-diameter ratios, conventional tube pneumatic conveying solutions can meet stable conveying requirements. However, small aspect ratio screws become a challenge in automatic screw feeding processes due to their structural characteristics. These screws are short in length with minimal difference between diameter and length. During pneumatic conveying in tubes, they are susceptible to airflow impact and friction from pipe inner walls, making their motion posture prone to losing control. Especially at turning points such as the three-way junction at the screwdriver head, they are prone to flipping or horizontal positioning, leading to interruptions in screw feeding. Once jamming occurs, manual shutdown and cleaning are required, which not only slows down the production pace but may also increase product assembly errors, affecting overall production quality.

I. Core Challenges of Automatic Feeding for Small Aspect Ratio Screws

The problems of screw flipping and jamming that occur during automatic feeding of small aspect ratio screws are not caused by a single factor but result from the combined effects of structural characteristics and conveying environment. From the screw itself, short screws with a length-to-diameter ratio <1.3 have relatively concentrated center-of-gravity distribution, making it difficult to maintain a stable axial posture under airflow propulsion and prone to flipping or deviation. From the perspective of the conveying system, conventional feeding solutions have tube path designs and airflow pressure controls optimized for conventional specification screws, making them unsuitable for the conveying requirements of small aspect ratio screws.

The structural design of the three-way junction at the screwdriver head further exacerbates the problem. As a critical turning node in screw conveying, airflow tends to become turbulent at this junction. Small aspect ratio screws that were barely maintaining their posture under the action of turbulent airflow can easily deviate from the predetermined conveying trajectory, resulting in flipped or horizontal screws that subsequently jam in the channels. The frequent occurrence of this situation disrupts the continuity of the automatic feeding system, compromises production pace, and raises concerns among enterprises about applying automatic feeding technology in small aspect ratio screw assembly scenarios.

II. Side-Mounted Solution: The Core Implementation Path for Stable Pneumatic Conveying of Small Aspect Ratio Screws

Addressing the pain points of automatic feeding for small aspect ratio screws, the side-mounted solution has become a key approach to effectively avoid jamming risks and achieve stable pneumatic conveying, thanks to its unique conveying logic. This solution breaks the conventional pattern of direct tube-to-head feeding, achieves standardized control of screw posture through optimized structural design, fundamentally reduces the possibility of screw flipping and jamming, while simultaneously improving production pace.

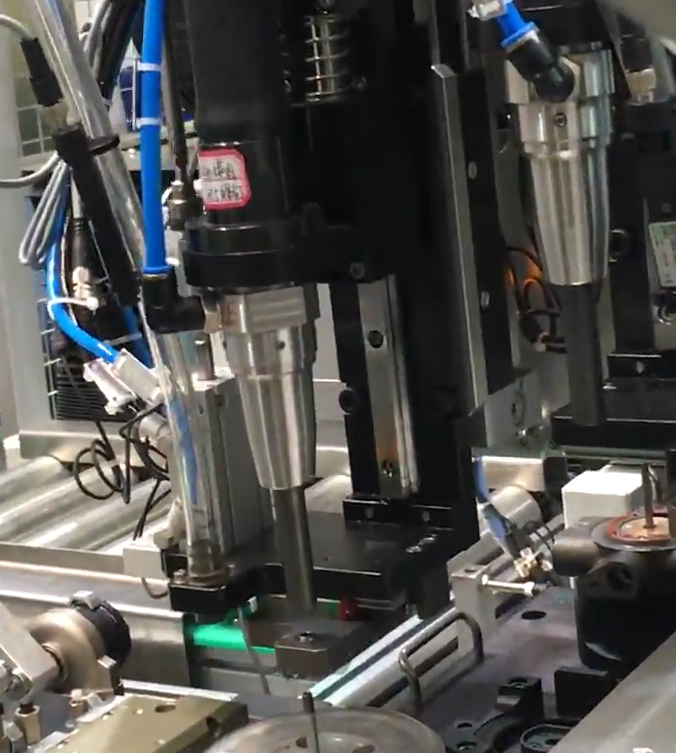

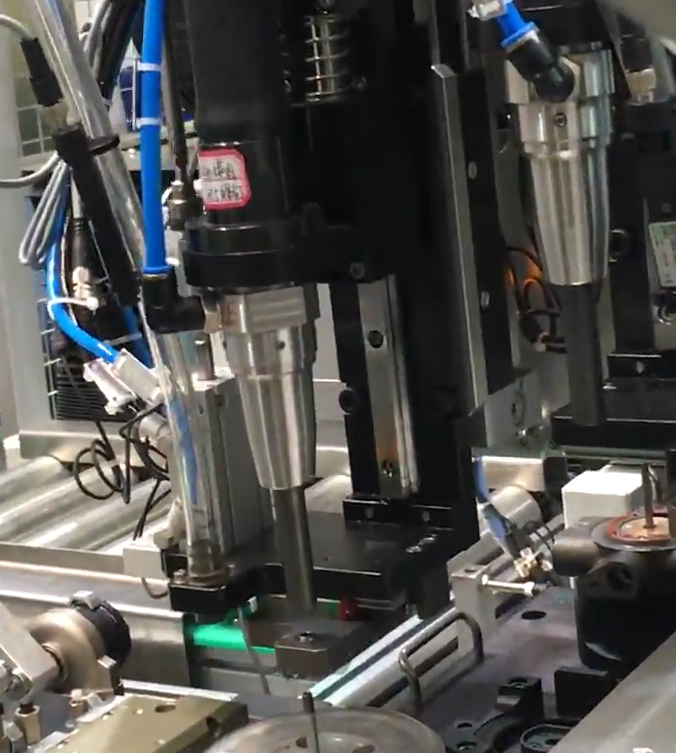

The workflow of the side-mounted solution is clear and fully compatible with the operational requirements of automatic feeding. The specific process is as follows: First, screws are directly blown by the feeding tube to the receiving platform of the module. The structural design of the receiving platform can effectively limit the screws, ensuring they maintain the correct axial posture at this location and avoid flipping during mid-conveyance. Subsequently, the receiving platform moves the posture-stable screws to a position below the screw suction station, coordinating with the suction device to complete the screw pickup action. After suction is completed, the equipment can proceed with subsequent tightening actions. Throughout the entire process, effective control by mechanical structures replaces direct airflow control of screw posture, significantly improving the stability of small aspect ratio screw conveying.

More noteworthy is that the side-mounted solution also features a screw pre-loading function. While the equipment is performing tightening actions, the feeding system can simultaneously convey the next screw to the receiving platform, achieving an operational mode of "tightening and screw preparation in parallel." This design effectively shortens the conveying and waiting time for individual screws. On the basis of ensuring feeding stability, it further improves production pace, solving the dilemma of "difficulty in balancing stability and efficiency" in small aspect ratio screw assembly.

More noteworthy is that the side-mounted solution also features a screw pre-loading function. While the equipment is performing tightening actions, the feeding system can simultaneously convey the next screw to the receiving platform, achieving an operational mode of "tightening and screw preparation in parallel." This design effectively shortens the conveying and waiting time for individual screws. On the basis of ensuring feeding stability, it further improves production pace, solving the dilemma of "difficulty in balancing stability and efficiency" in small aspect ratio screw assembly.

III. Specification Compatibility Advantages of the Side-Mounted Solution

In actual production scenarios, enterprises often face the problem of diverse screw specifications. When screw specifications are consistent with only length differences, the side-mounted solution can effectively enhance the compatibility of automatic feeding systems, avoiding frequent replacement of feeding modules due to minor specification adjustments and reducing production debugging costs. Its core advantage lies in easily accommodating the conveying needs of different-length screws of the same specification through optimized structural layout of feeding channels and the use of adjustable limit components, without requiring major equipment modifications.

In assembly scenarios for small aspect ratio screws, if enterprises have assembly requirements for multiple lengths of the same specification screws, the compatibility advantages of the side-mounted solution become more prominent. Stable conveying of different-length screws can be completed without adjusting core equipment parameters, further expanding the application scope of automatic feeding technology. This gives enterprises greater flexibility when dealing with multi-specification screw assembly requirements and reduces the time and labor costs associated with equipment debugging.

IV. Optimization and Application Prospects of Automatic Screw Feeding Technology

The development of automatic screw feeding technology has always centered on the core requirements of "stability and adaptability." The emergence of the side-mounted solution effectively addresses the pain point of stable pneumatic conveying for small aspect ratio screws and also promotes the penetration of automatic feeding technology into more segmented assembly scenarios. As intelligent manufacturing continues to deepen, enterprise requirements for automatic feeding systems will further increase. Beyond adapting to special specifications such as small aspect ratio screws, there will also be pursuit of higher intelligence levels, such as real-time monitoring of feeding status through sensors and adjusting conveying parameters through data, making automatic feeding systems better suited to flexible production needs.

Stable pneumatic conveying of small aspect ratio screws is not unachievable. Through the scientific process of "pneumatic conveying-receiving-transfer-suction," the side-mounted solution fundamentally solves the problems of screw flipping and jamming. With its screw pre-loading function, it improves production pace, and also possesses excellent specification compatibility advantages, providing a reliable solution for automated assembly of small aspect ratio screws. In the application process of automatic feeding technology, enterprises need to select appropriate feeding solutions based on the screw specification characteristics of their own products to fully leverage the advantages of automatic feeding technology. In the future, as technology continues to optimize, automatic feeding systems will achieve stable application in more segmented scenarios, providing more solid support for automation upgrading in the manufacturing industry.