Causes and Control Countermeasures of Torque Instability in Torque Tools for Industrial Assembly

In industrial assembly processes, torque instability in torque tools is a common problem encountered by many manufacturing enterprises. Torque fluctuations not only affect product consistency but may also lead to loose screws, stripped threads, or even structural failure, and in severe cases, increase rework and after-sales risks. So, what exactly causes torque instability in torque tools?

1. Insufficient Accuracy of Torque Tools is One of the Most Common Causes

Clutch-type torque tools inherently have relatively large dispersion.

Traditional clutch-type torque tools rely on mechanical springs and clutch mechanisms to control torque output, which inherently have certain torque dispersion, typically making it difficult to meet high-consistency assembly requirements.

• Springs are significantly affected by fatigue

• Greatly influenced by temperature, wear, and usage time

• Relatively low repeat accuracy

As usage time increases, the elastic decay of springs further amplifies torque fluctuations, causing the actual output torque to deviate from the set value, thereby manifesting as torque instability.

Applicable Recommendation:

Clutch-type torque tools are more suitable for scenarios with low torque consistency requirements, such as general structural component assembly.

2. Torque Instability in Servo Torque Tools is Mostly Related to Strategy Settings

Compared with traditional tools, high-precision servo torque tools inherently possess higher torque control capabilities. If torque instability occurs, it is often not a hardware problem but rather improper tightening strategy settings.

When rotational speed is too high in hard-joint working conditions, torque overshoot is likely to occur

In hard-joint scenarios (such as metal-to-metal, rigid structures), if the rotational speed is set too high during the final tightening stage:

• Motor inertia cannot be released in time

• Torque rises too quickly

• Torque overshoot is likely to occur

The final result is:

The actual tightening torque is higher than the set value, causing torque instability

Optimization Recommendations:

• Reduce rotational speed during the final tightening stage

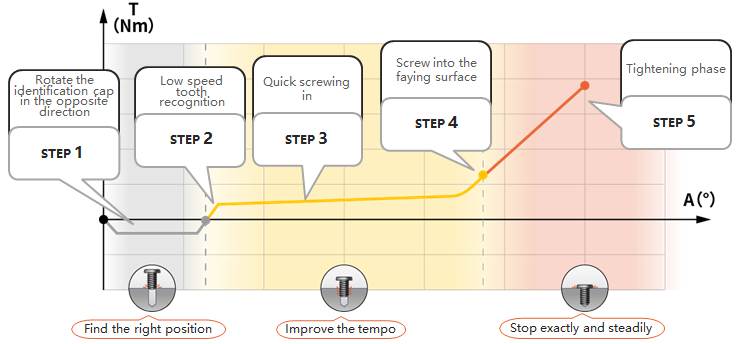

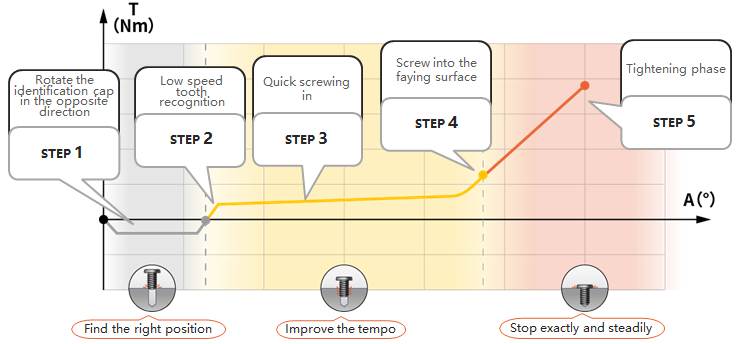

• Adopt a multi-stage tightening strategy (fast screw insertion + low-speed final tightening)

• Enable torque + angle control strategy

3. Wear of Mechanical Components Caused by Long-term High-frequency Use

Even high-end torque tools inevitably experience internal wear problems after long-term high-frequency use:

• Increased gear meshing clearance

• Changes in transmission efficiency due to bearing wear

• Sensor zero-point drift

These directly affect the stable output of torque, manifesting as:

• Increased torque fluctuations under the same setting

• Decreased repeat accuracy

• Inconsistent assembly results across different batches

4. Lack of Regular Calibration is the Key Reason for Amplified Torque Deviation

Many enterprises neglect the importance of regular calibration when using torque tools. Even high-precision servo torque tools require calibration to compensate for errors caused by wear and aging.

The role of regular calibration includes:

• Correcting sensor deviation

• Compensating for mechanical wear errors

• Ensuring torque data is authentic and reliable

Recommended Cycle: ISO 9001 quality standards do not specify calibration cycles and frequency; they depend on several factors such as tool usage and environment. High-frequency applications may require calibration once per day, while low-frequency applications may only require calibration once per year.

Four tips for determining calibration frequency:

• Check the torque tool manufacturer's calibration recommendations (should calibration be performed after reaching a specific number of cycles?)

• How stable has the torque tool been in the past?

• How critical are the related measurements?

• What risks and consequences would arise from exceeding tolerances?

During use, tools need regular torque verification and system calibration for deviation compensation. The actual calibration cycle needs to be determined based on on-site usage conditions, measuring instrument usage, frequency of use, and the safety requirements of the assembled products. We recommend calibrating the measurement system based on site conditions every 250,000 cycles/1 month or 500,000 cycles/2 months. The general calibration method is: test 25 sets of tool display readings (x) and dynamic torque tester readings (y), perform linear fitting y=kx+b, and enter the mean percentage deviation from the target torque (k) and deviation value (b) into the corresponding boxes in the controller interface. The percentage K adjustment is coarse tuning, and deviation B adjustment is fine tuning.

5. How to Systematically Solve the Problem of Torque Instability in Torque Tools?

Comprehensively speaking, solving torque instability problems should start from the following aspects:

Reasonable Model Selection: Prioritize servo torque tools for high-consistency assembly

Strategy Optimization: Set appropriate rotational speed and control methods based on hard or soft joints

Process Monitoring: Introduce torque and angle data monitoring to improve traceability

Regular Maintenance and Calibration: Reduce systematic errors caused by wear

Torque instability in torque tools is not caused by a single factor but is the result of the combined effects of tool accuracy, tightening strategy, working conditions, and maintenance management. Only through systematic analysis and optimization can we truly improve assembly quality and product consistency.