In automated assembly and manual tightening operations, the rotational speed of screwdrivers is often regarded as a key metric for improving production cycle times. Many people believe that:

The higher the speed, the faster the screwing, and naturally, the higher the efficiency.

However, on actual assembly floors, this conclusion often doesn't hold true. Is faster really better when it comes to screwdrivers? The answer is actually: not necessarily, and it may even backfire.

I. Screwdriver Speed Does Not Equal Assembly Efficiency

Theoretically, increasing screw screwdrivers speed can indeed shorten the rotation time for individual screws, but assembly efficiency is not determined solely by "how fast it spins." Instead, it is determined by the stability and success rate of the entire tightening process.

In actual production, excessive speeds often lead to the following problems:

The screw spins at high speed before proper thread engagement, easily causing cross-threading;

Initial thread engagement becomes unstable, resulting in misaligned screws and stripped threads;

Excessive inertia during final tightening leads to torque overshoot;

As a result, frequent rework occurs, and cycle times actually slow down.

The final outcome is:

While single tightening time decreases, overall cycle time is severely delayed by rework.

II. How to Improve Assembly Efficiency

When tightening bolts, the primary function of the bolt is to provide appropriate clamping force for the connected components. However, in actual tightening processes, only about 10% of the applied torque is ultimately converted into effective clamping force. To ensure assembly quality meets expected standards, production lines cannot simply complete tightening in one step. Instead, reasonable tightening strategies must be developed based on the bolt's operating environment and conditions.

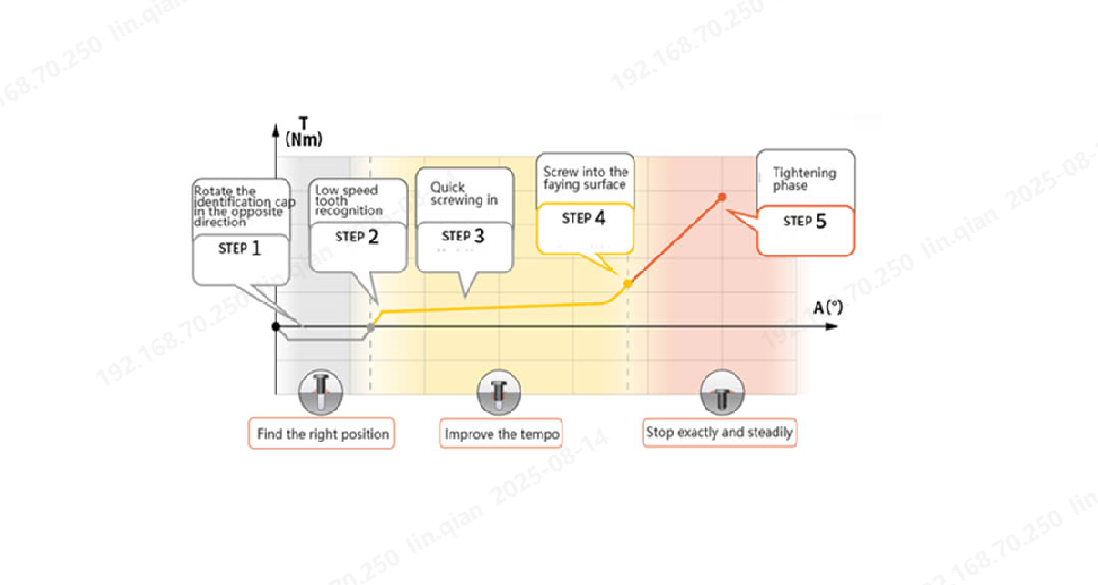

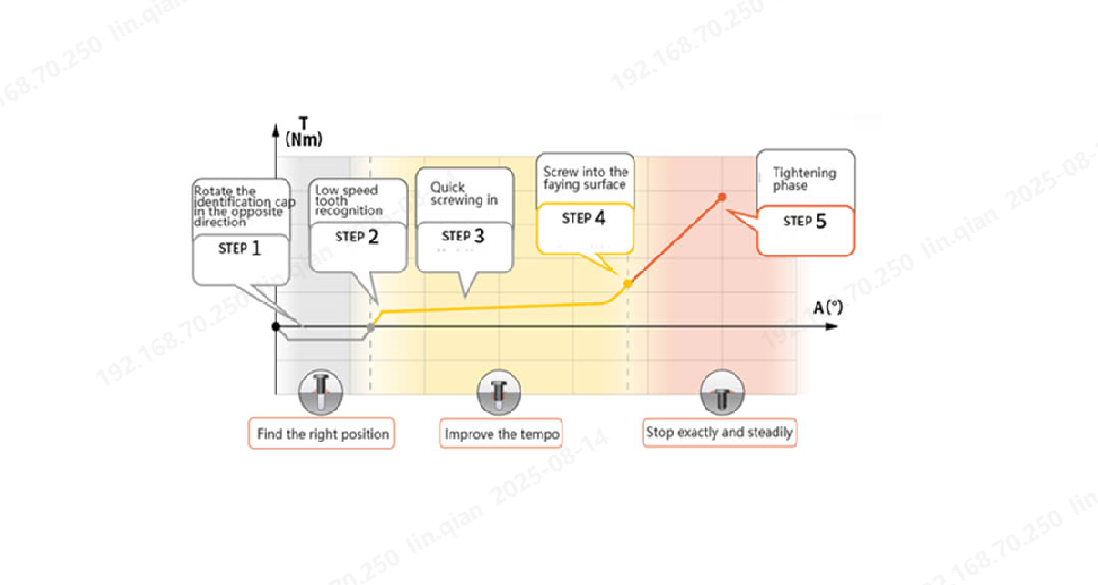

The bolt tightening process is not accomplished in a single step but rather through multi-step tightening—this is the basis for developing tightening strategies.

To meet practical working condition requirements, Danikor intelligent tightening tools require different settings for speed, torque, and angle at each step of the tightening process.

Reverse Thread Engagement :Use low-speed reverse rotation to properly align the screw with the thread and enter the hole, preventing screw tilt. The maximum torque for this stage is generally set at approximately 30% of the target value, and the duration should not be too long.

Low-Speed Thread Engagement :At lower speeds, allow the screw to engage 1-2 threads. This helps prevent misaligned screws and reduces the risk of cross-threading. The speed is typically recommended to be slightly above the seating point torque, or can be set to the upper limit of the target torque.

Fast Screwing:At this stage, the screw is driven in quickly at high speed to improve production efficiency. The speed is usually set to the maximum value allowed by the equipment or process.

Seating Approach:When the screw approaches contact with the workpiece, reduce the speed so that torque gradually approaches a small fraction of the target value, ensuring stable and reliable seating position.

Final Tightening:After the contact phase, perform the final tightening. This step is executed at lower speed, which helps reduce torque impact and makes the clamping force more uniform and reliable.

By setting different torque, angle, and time limits for each step, and employing advanced tightening strategies such as clamping torque control, not only can abnormal conditions like floating screws and misaligned screws be monitored in real-time, but assembly efficiency can also be improved while ensuring precision. This step-by-step strategy helps freely combine settings for different stages in automated production according to different workpieces and cycle time requirements, thereby developing the most suitable tightening solution and ensuring final assembly quality.