Screw feeder are widely used in electronics manufacturing, automotive assembly, home appliance production, and other industries. The system mainly consists of core components such as a hopper, pushing mechanism, linear vibration track, screw separation mechanism, blow tube, and control system, forming a complete automated conveying loop. It achieves fully automated flow of screws from storage to the screwdriving station, significantly reducing manual intervention and avoiding issues such as missed feeding, wrong feeding, and low efficiency associated with manual screw handling. This article will analyze the working principle of screw feeders from aspects of structural composition, workflow, and the functions of core components, exploring in depth how they accomplish accurate screw conveying through the coordinated cooperation of various mechanisms.

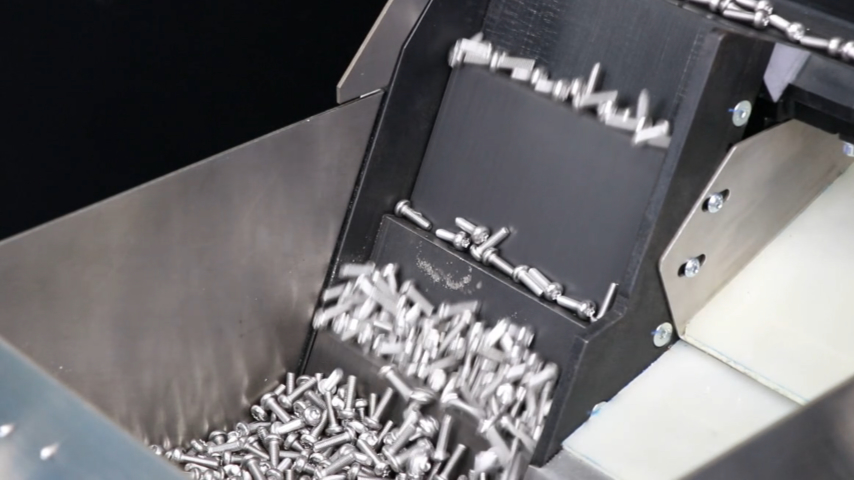

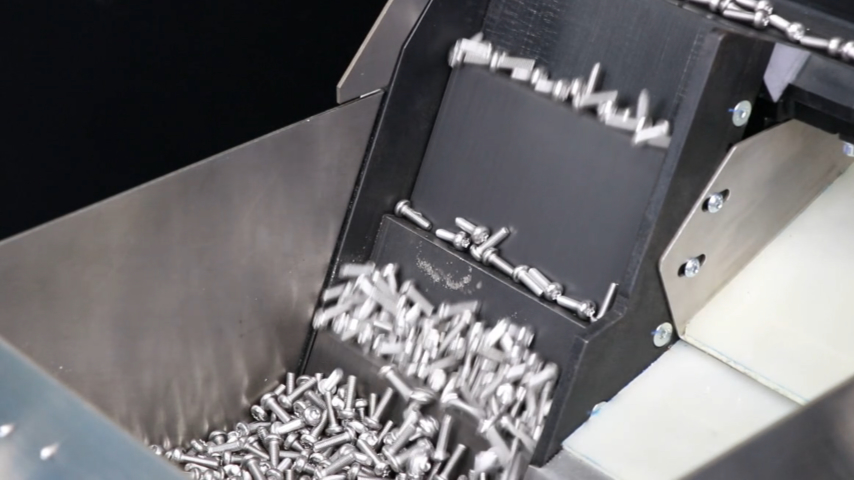

I. Hopper: Screw Storage and Initial Feeding

The hopper is the fundamental component of the screw feeder, primarily used for bulk storage of screws to be conveyed. Its structural design directly affects the feeding efficiency and the smoothness of subsequent conveying. The bottom of common step feeder screw feeder hoppers typically adopts an inclined structure. The core principle of this design is to utilize gravity to allow screws in the hopper to naturally slide down to the designated pushing area, preventing screw accumulation and jamming inside the hopper. The hopper capacity should be selected according to production line capacity requirements and screw specifications. The hopper capacity of screw feeders for large production lines can reach over 4L, and the bottom is equipped with a low-level sensor that, combined with an automatic replenishment device, enables long-duration uninterrupted feeding. Small precision production lines place greater emphasis on compactness and flexibility to save space.

II. Pushing Mechanism: Primary Conveying Power Source for Screws

The pushing mechanism is the core power component that enables initial screw feeding in the screw feeder . Its operational stability directly determines the continuity of screw feeding. The pushing mechanism mainly consists of a cylinder, push plate, and reset device. When screws in the hopper slide down to the pushing area, the control system will send a start signal based on the remaining screw quantity in the subsequent linear vibration track, driving the cylinder to move the push plate upward and push the screws step by step to the linear vibration track. After pushing is completed, the cylinder drives the push plate to quickly reset. At this time, screws in the hopper will naturally replenish to the pushing area under gravity, waiting for the next pushing action, thus forming a stable pushing cycle.

III. Linear Vibration Track: Screw Orientation Correction and Sorting Conveying

The linear vibration track is the key component in the screw feeder that achieves screw orientation correction and sorting conveying. Based on the electromagnetic vibration principle, the electromagnetic vibrator at the bottom of the track generates high-frequency micro-vibrations, driving the track to perform high-frequency linear reciprocating motion. Under the vibration effect, screws will be conveyed forward along the track. When screws are conveyed on the track, only those in the preset orientation (usually head-up, thread-down) can smoothly advance along the guide groove on the inner side of the track. Screws with unqualified orientations (such as head-down, tilted, etc.) will be blown off the track by the air blowing mechanism equipped on one side of the linear vibration track, causing them to fall back into the hopper for secondary screening. The vibration frequency of the linear vibration track can be adjusted through the control system according to parameters such as screw weight and size to achieve appropriate conveying speed. Advanced screw feeder linear vibration tracks also feature adaptive functions that can automatically adjust vibration frequency based on weight, ensuring stable forward movement regardless of whether there are many or few screws on the track, guaranteeing smooth and jam-free screw feeding.

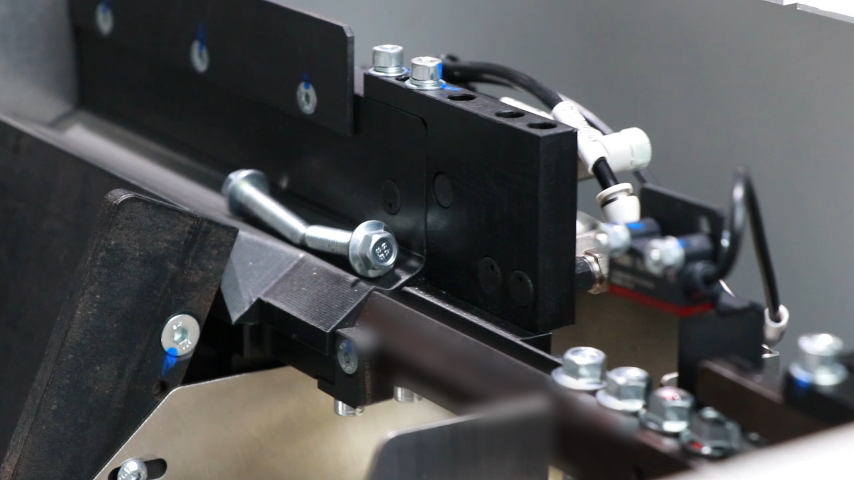

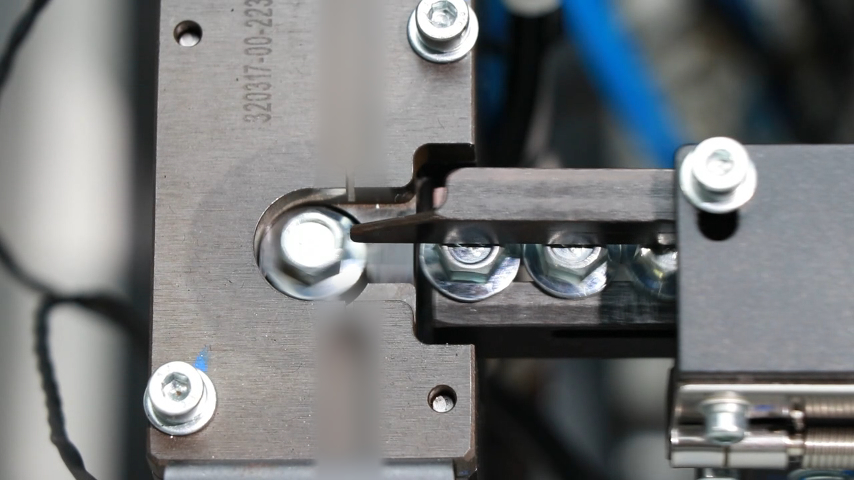

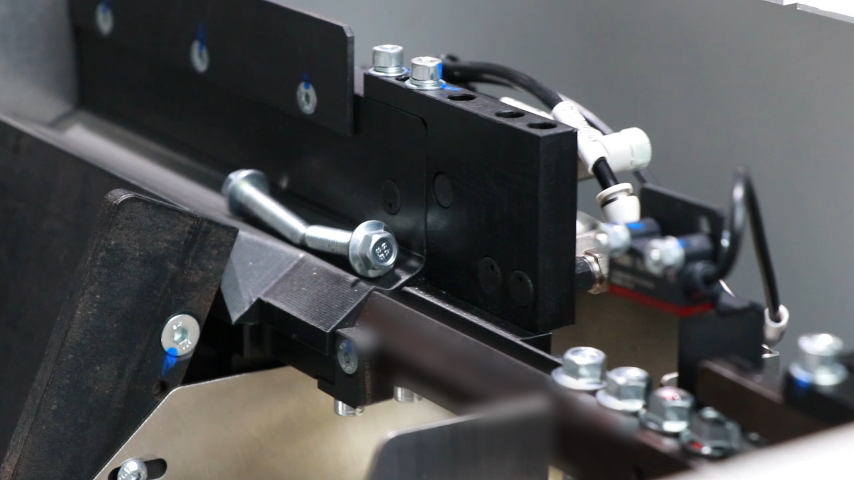

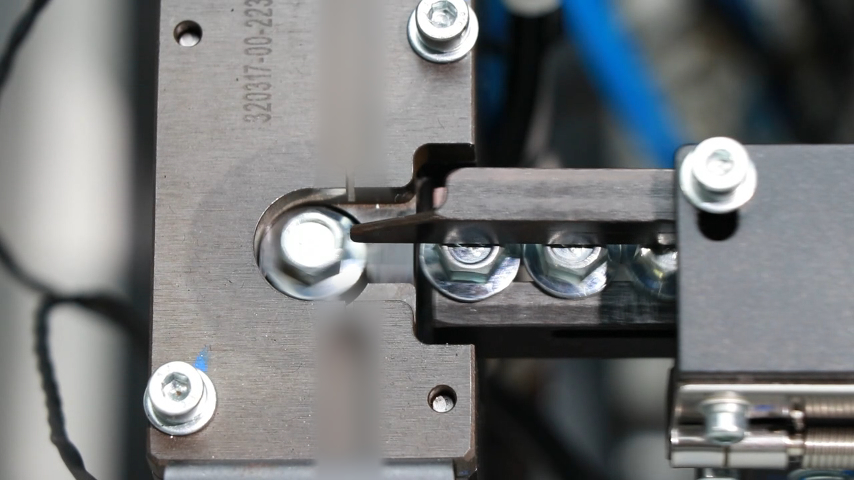

IV. Screw Separation Mechanism: Separating Screws for Single-Piece Feeding

The screw separation mechanism is the core component that enables single-piece feeding of screws in the screw feeder. Its function is to separate the continuous stream of screws conveyed by the linear vibration track into individual screws and send them into the blow tube. When screws are conveyed to the inlet of the separation mechanism through the linear vibration track, the control system will send a separation signal according to the needs of the screwdriving process, allowing a single screw to fall into the inlet of the blow tube. The separation frequency will be synchronized with the pace of the subsequent screwdriving process, ensuring that one screw is supplied for each screwdriving action. A presence detection sensor can also be equipped at the separation mechanism of the screw feeder to avoid missed or multiple separations.

V. Blow Tube: Final Delivery Channel for Screws

The blow tube is the key channel for feeding screws from the separation mechanism to the screwdriving module nose. When a single screw falls into the blow tube, the control system will activate the air pressure device to introduce compressed air into the blow tube. Under the push of air pressure, the screw will travel at high speed inside the blow tube. The inner wall of the blow tube is usually treated to be smooth to reduce friction when the screw moves forward inside the tube, preventing the screw from jamming or having its threads scratched due to friction. Meanwhile, the length and diameter of the blow tube are designed according to the distance of the screwdriving station and screw specifications to ensure that the screw can quickly and smoothly reach the module nose under air pressure, after which the screwdriving mechanism initiates to complete the screwdriving action.

Through the coordinated cooperation of the above components, the screw feeder achieves fully automated conveying of screws from storage to screwdriving, greatly improving production efficiency and screwdriving quality. It has been widely used in the assembly of products such as mobile phones, computers, and tablets in the electronics industry; component assembly in the automotive industry; production of home appliances such as refrigerators, washing machines, and air conditioners; as well as high-end manufacturing fields like medical devices and precision instruments. In the future, it will also develop toward greater precision, higher efficiency, and smarter intelligence, further promoting the intelligent upgrade of automated production lines.